Battery Management Technology Explained

Why Battery Management Matters?

Protection

Lithium-ion batteries are highly sensitive to overvoltage, which can lead to catastrophic failure and fire hazards, and undervoltage, which can cause severe capacity loss. To mitigate these risks, every battery pack must have a protection circuit to keep cell voltages within safe limits. Protection circuits also play a crucial role in preventing overcurrent and overheating.

Accurate voltage measurement is critical for setting safe and effective thresholds, as each cell's voltage directly correlates with its state of charge. This accuracy is essential for achieving maximum capacity while ensuring safety. Our system offers a remarkable 1 millivolt (mV) accuracy, allowing precise setting of voltage thresholds. Additionally, our technology simultaneously measures all cells and current, providing best-in-class impedance measurement—an essential factor in determining a battery's state of health.

Nova's precision technology ensures that voltage, current, and temperature remain within optimal boundaries, enabling tighter safety margins and improved battery performance. This level of accuracy leads to more reliable protection, optimized capacity, and a longer battery life.

Cell Balancing

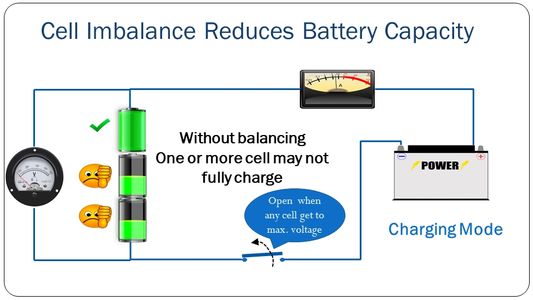

Manufacturing tolerances and temperature variations mean no two batteries are identical. These differences can cause imbalances in multi-cell packs, leading to varying cell voltages. Since lithium-ion batteries are sensitive to overvoltage and undervoltage, protection circuits might shut down charging or discharging when a single cell hits its voltage limit, potentially reducing battery pack capacity.

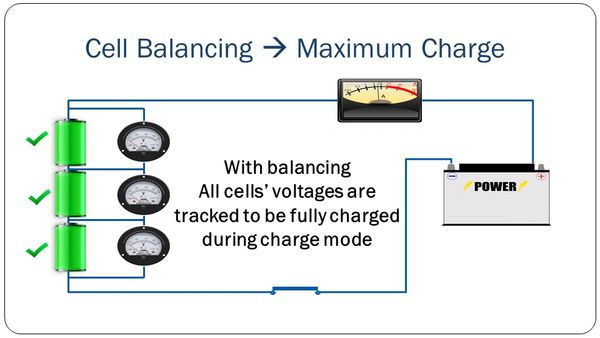

Our system simultaneously measures all cell voltages with 1 millivolt accuracy, allowing us to detect imbalances and apply corrections early. By focusing on each cell's internal impedance, we can ensure even charge distribution and avoid overcharging or undercharging. This precision is key to maintaining a balanced battery pack, which is critical for its longevity and full capacity throughout its life.

Without proper balancing, small imbalances can lead to capacity discrepancies, reducing the overall performance of the battery pack over time. By integrating simultaneous and accurate voltage measurement, which enables impedance-based correction, our system ensures consistent battery pack performance under all conditions.

Fuel Gauging

Health Monitoring / Assessment

Health Monitoring / Assessment

Accurately estimating a battery's state of charge is one of the most challenging tasks in battery management. It requires precision in cell balancing, voltage and current measurements, and the consideration of temperature's impact on these metrics. The industry has developed various algorithms to tackle these challenges, but achieving consistent accuracy remains a key factor in creating reliable estimates.

When estimates are off, it can lead to either premature warnings, causing users to believe their battery is nearly empty when it isn't, or a lack of warnings when the battery is about to run out, resulting in abrupt power loss.

Nova's advanced coulomb counting and state-of-charge measurement technology sets a new standard in accuracy with 0.02% repeatability. This level of precision allows for a nearly perfect estimation of battery charge and usage time by meticulously tracking the charge flowing in and out of the battery. With Nova, you can rely on consistent and reliable SOC readings, ensuring accurate battery management, even as batteries age.

Health Monitoring / Assessment

Health Monitoring / Assessment

Health Monitoring / Assessment

Battery health monitoring is essential for maximizing performance, lifespan, and safety. As batteries age, their internal impedance increases—a key indicator of degradation long before voltage or temperature show warning signs. Traditional methods rely on external sensors or inferred estimates, adding complexity while offering limited accuracy.

Nova Semiconductor takes a fundamentally better approach. With its patented Digitally Assisted Analog (DAA) architecture, the NB1600 measures each cell’s impedance directly, at milliohm-level resolution, in real time. Unlike systems that require extra wiring, sensors, or thermal workarounds, Nova achieves this insight using the same connections as any standard BMS. No added components. No guesswork.

This enables a more precise view into each cell’s state of health, making Nova’s IC not just a battery monitor—but a diagnostic tool. It empowers OEMs and system designers to predict failures early, balance cells more effectively, and extend battery life without redesigning their systems.

Nova turns battery behavior into something measurable—what once felt magical now becomes actionable.

PROTECTION CIRCUIT & Unbalance Cells Interact...

Charge Cycle

Discharge Cycle

with Cell Balancing IMPLEMENTed...

Charge Cycle

Discharge Cycle

Discharge Cycle

Discharge Cycle

Discharge Cycle

Discharge Cycle

THE PROBLEM

Accurate measurement is the cornerstone of effective battery management. A key challenge in managing lithium-ion batteries, particularly lithium iron phosphate (LFP), is the relatively flat curve between open-circuit voltage and state of charge. This flatness means even slight deviations in measurement can lead to significant errors in determining battery status. Historically, the industry has aimed for an accuracy of about 5mV, which is equivalent to roughly 0.1%. Achieving this level of precision is challenging and expensive, especially with brute-force methods.

Compounding this challenge is the need to maintain accuracy across a range of temperatures and cell voltages to ensure optimal battery performance. Brute-force approaches often fall short of delivering consistent accuracy under these varying conditions, leading to various shortcomings, including forcing users to implement costly calibration. This inconsistency has driven the search for more refined and sophisticated solutions that meet the rigorous demands of modern battery technology.

THE SOLUTION

Nova's patented technology provides a breakthrough in battery management. Our digitally assisted analog approach allows us to achieve an impressive 1 millivolt accuracy in cell voltage measurement and 0.02% repeatability in coulomb counting, all in a cost-effective and elegant manner. This innovation not only ensures high performance but also makes advanced battery management technology accessible to a broader range of products.

The lack of affordable and effective cell balancing solutions has led many low-cost consumer products to skip this critical feature, resulting in significantly shorter battery life. Often, when a battery fails, the entire device becomes disposable, contributing to waste and environmental harm.

Nova's technology aims to change that by providing a reliable and economical solution to battery management. With our approach, battery packs can retain their full capacity throughout their intended lifespan. Say goodbye to early battery degradation and the unnecessary disposal of entire devices. With Nova, batteries perform as they should, for as long as they should.

Saving our planet, one battery pack at a time!

Copyright © 2019-2026 Nova Semiconductor INC. - All Rights Reserved.

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.